A178

Standard Specification for Electric-Resistance-Welded Carbon Steel and Carbon- Manganese Steel Boiler and Superheater Tubes

1. Scope*

1.1 This specification2 covers minimum-wall-thickness, electric-resistance-welded

tubes made of carbon steel and carbon-manganese steel intended for use as

boiler tubes, boiler flues, superheater flues, and safe ends.

NOTE 1—Type C and D tubes are not suitable for safe-ending for forge welding.

1.2 The tubing sizes and thicknesses usually furnished to this

specification are 1⁄2 to 5 in. [12.7 to 127 mm] in outside diameter and

0.035 to 0.360 in. [0.9 to 9.1 mm], inclusive, in minimum wall thickness.

Tubing having other dimensions may be furnished, provided such tubes

comply with all other requirements of this specification.

1.3 Mechanical property requirements do not apply to tubing smaller than

1⁄8 in. [3.2 mm] in inside diameter or 0.015 in. [0.4 mm] in

thickness.

1.4 Optional supplementary requirements are provided and when desired,

shall be so stated in the order.

1.5 The values stated in either inch-pound units or SI units are to be

regarded separately as standard. Within the text, the SI units are shown

in brackets. The values stated in each system are not exact equivalents;

therefore, each system must be used independently of the other. Combining

values from the two systems may result in nonconformance with the

specification.

The inch-pound units shall apply unless the “M” designation of this

specification is specified in the order.

2. Referenced Documents

2.1 ASTM Standards:

A 450/A 450M Specification for General Requirements for Carbon, Ferritic

Alloy, and Austenitic Alloy Steel Tubes3

E 213 Practice for Ultrasonic Examination of Metal Pipe and Tubing4

E 273 Practice for Ultrasonic Examination of Longitudinal Welded Pipe and

Tubing4

3. Ordering Information

3.1 Orders for material under this specification should include the following,

as required, to describe the desired material adequately:

3.1.1 Quantity (feet, metres, or number of lengths),

3.1.2 Name of material (electric-resistance-welded tubes),

3.1.3 Grade (A, C, or D, Table 1),

3.1.4 Size (outside diameter and minimum wall thickness),

3.1.5 Length (specific or random),

3.1.6 Optional requirements (product analysis, Section 7; crush test,

Section 10; hydrostatic or nondestructive electric test, 11.6),

3.1.7 Test report required (Certification Section of Specification A 450/A

450M),

3.1.8 Specification designation,

3.1.9 Individual supplementary requirements, if required,and

3.1.10 Special requirements.

4. Manufacture

4.1 The steel for Grade D shall be killed.

4.2 Tubes shall be made by electric-resistance welding.

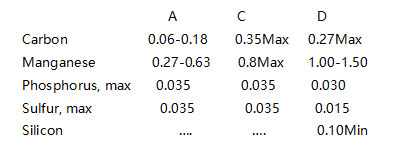

1, Chemical composition:

2, Mechanical Properties:

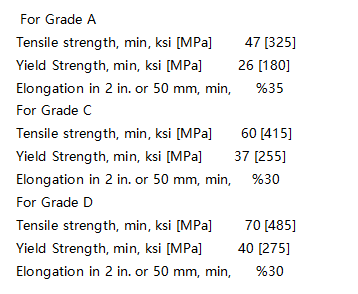

3, Permissible Variations in Wall Thickness A

A, These permissible variations in wall thickness apply only to tubes, except internal-upset tubes, as rolled or cold-finished, and before swaging, expanding, bending, polishing, or other fabricating operations.

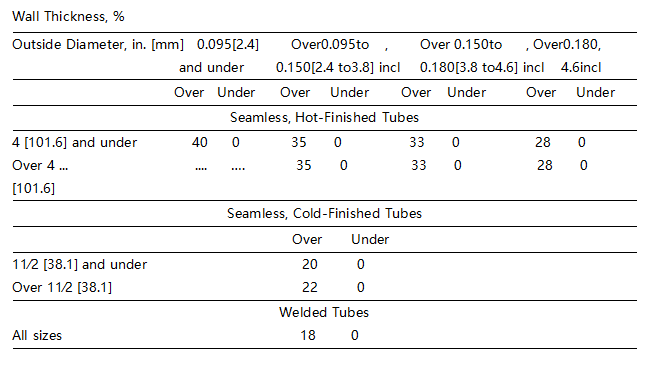

4, Permissible Variations in Outside DiameterA

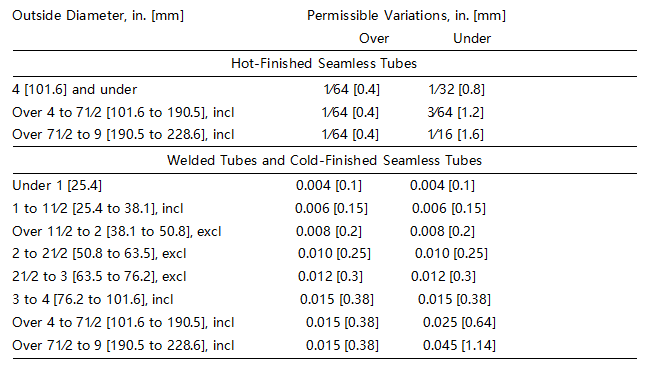

5, Hydrostatic Test Pressures

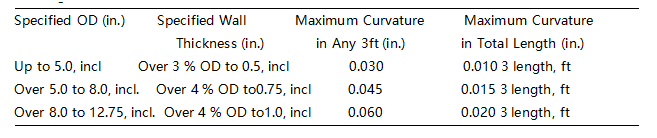

6, Straightness Tolerances

SUNRISE is well-known as one of the leading astma178 electric resistance welded carbon steel and carbon manganese steel boiler and superheater tubes manufacturers and suppliers in China for its quality products and excellent service. We warmly welcome you to buy the quality and durable steel products from our factory.